Published On Jun 16, 2017

Super thanks: $ THANKS

Paypal:https://paypal.me/MichaelPaleyAU

bitcoin:BC1QL0VA99HFHLHC8PW5SU9ERQXV4A0FDN6HUXQYCA

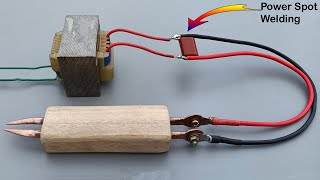

Step by step tutorial how to make a Spot Welder.

#michaelpaley

Handfree mode

Power control

Use old microwave and vacuum cleaner

Electric Circuit - https://drive.google.com/file/d/0B1O1...

Resistance spot welding (RSW) is a process in which contacting metal surfaces are joined by the heat obtained from resistance to electric current.

Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the 0.5 to 3 mm (0.020 to 0.118 in) thickness range. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a lot of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). That permits the welding to occur without excessive heating of the remainder of the sheet.

The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude and duration of the current. The amount of energy is chosen to match the sheet's material properties, its thickness, and type of electrodes. Applying too little energy will not melt the metal or will make a poor weld. Applying too much energy will melt too much metal, eject molten material, and make a hole rather than a weld. Another feature of spot welding is that the energy delivered to the spot can be controlled to produce reliable welds.